Fertilisers and spreader calibration

30 March 2018As part of the Soil and Nutrient Network farms project both West Lothian and Roxburghshire farms demonstrated on farm the importance of fertiliser products, spreader maintenance and calibration.

At West Lothian 5 different fertiliser products were compared. Figure 1 shows Top left 20:8:12 + S, top right 20:10:10, bottom right 34.5 N, bottom left 25:5:5 and centre 5:24:24. From comparing the various fertilisers from different manufacturers the difference in particle size was obvious within the blends. The two compounds on the left were both from the same manufacturer but the difference in texture of the particles was very different. This will affect the flow rate of fertiliser through the machine as well as the spread pattern of the fertiliser.

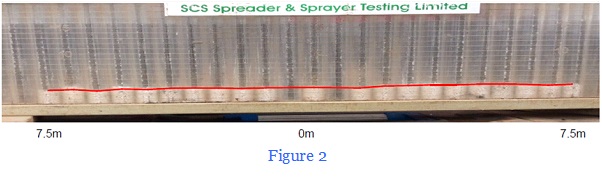

In order to compensate for different fertiliser types it is important to check the spread pattern of the fertiliser spreader and alter settings if necessary. At both the nutrient network farms the fertiliser spreaders were inspected to check spread patterns. This is done by setting out trays over the spread width and measuring the quantities of fertiliser collected in the trays. The weights are then graphed over the width of the spreader and a coefficient of variation (CV) is calculated to assess how even the spread pattern is. Anything below 15% is classed as acceptable. Over this value significant financial losses could be noted in the crop. At current prices, the loss of margin at a CV of 25% (often found before testing) against an achievable CV of 5% is around £20/ha in wheat and winter oilseed rape. The cost of a professional test would be recouped over 12ha. In order to ensure that this is achieved, the spreader veins should be monitored for wear and replaced as soon as possible.

Figure 2 illustrates the measure of Nitram spread at 200kg/ha over 15 metres. The result was a coefficient of variation of 4.68%.

Ensuring fertiliser spreaders are well maintained and calibrated can help to ensure that fertilisers are applied as accurately and evenly as possible. Good maintenance and calibration can help to avoid fertiliser striping, crop loss, uneven ripening and environmental issues.

Andrew Baird & Craig Bothwell, SAC Consulting

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service