Milk Manager News March 2023 – Preventing Silage Slippage This Season

10 March 2023There are many risk factors associated with slippage of silage clamps, which can cause significant spoilage of silage around the area of slippage. The result is poorer quality silage and possible mycotoxin related issues in cattle. It is worth assessing the risk factors for slippage on your farm if this has been an issue in the past. These include:

Maturity of Grass at Cutting

Young, leafy grass swards, typical of multi-cut silage systems, with high D values of around 75% and low NDF contents less than 45% have a higher risk of slippage. This is because the grass has less structural fibre to help hold the silage in place in the clamp and is also less likely to contain more fibrous varieties such as cocksfoot, timothy or fescues. Another contributory factor to slippage is the inclusion of white clover, which has a lower fibre and higher water content than perennial ryegrasses.

Younger grass also has a higher oil content (up to 10%) compared to more mature grass (which can be as low as 3% when fully headed), and interestingly some farmers that have had problems with slippage have commented that their silage felt oily. Newer grass varieties may also have a higher oil content.

Although higher quality grass can increase the risk of slippage, the aim should still be to make the best quality silage possible to maximise animal performance, but focus on what can be done in terms of clamp filling, consolidation and forage chop length to reduce the risk.

Chop Length

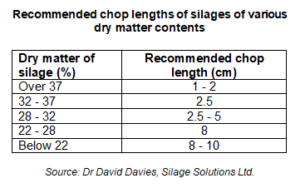

Slippage tends to occur more in clamps where the silage has a shorter chop length. This is especially true with low dry matter silages. For multi-cut silages a minimum chop length of 5cm is recommended, even if the dry matter (DM) is over 30%. Chop length should vary with DM, with a longer chop length for wetter material.

Filling the Clamp

The clamp should be filled in shallow, flat layers with an angle no greater than 20 degrees. The greater the angle, the greater the risk of slippage, especially if consolidation and silage density are not consistent throughout the clamp. Layers should be no more than 15cm depth if the target dry matter is achieved, although can be up to 25cm if the DM is less than 25%.

Consolidation

A recent study by AHDB on ten farms that had issues with clamp slippage revealed that inconsistent consolidation was the main risk factor. Generally the density of silage is greater lower down the clamp, but if consolidation is uneven throughout, any heavier (denser) areas of silage on top of lighter (less dense) areas, could encourage slippage. Areas of poor consolidation, where there may still be oxygen present, are likely to have more acetic acid produced during the fermentation. A more acetic acid fermentation also produces CO2 and water. These areas of poorer fermentation will end up being wetter, with silage of higher density and therefore more likely to slip.

Over consolidation can also cause a problem, particularly with wetter material (less than 25% DM). Over rolling can cause the grass plant cells to burst, releasing more sap and lubricating the silage.

Clamp Dimensions

Slippage is more likely to occur in wider and higher clamps, with higher clamps having more vertical weight pushing down on the base of the clamp. Wider clamps tend to have less frictional forces exerted on the silage from the walls and so are less effective at holding the silage in place.

Top Tips

The following recommendations should help reduce the risk of slippage:

· Adjust the chop length depending on the dry matter and quality of the grass. A longer chop length is required with wetter silages and those with a higher digestibility (young, leafy grass).

· Target a DM of 28-32% with a fast wilt of less than 24 hours to reduce nutritional losses.

· Fill the clamp in shallow layers of the follow depths for different dry matters. The angle of the layers should be no more than 20 degrees.

- 15cm layers for DM over 28%

- 20cm layers for DM between 25-28%

- 25cm layers for DM less than 25%

· Ensure even rolling of all layers so that consolidation and therefore silage density is consistent throughout the clamp.

· Do not overfill clamps and if slippage has previously been an issue, reduce the height of the grass ensiled and bale any excess.

· If the clamp is very wide, consider splitting it in two to create narrower clamps. This will also aid keeping quality, with less risk of aerobic spoilage, as it will take fewer days to cross the silage face.

lorna.macpherson@sac.co.uk; 07760 990901

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service