Pesticide Information Note: Spray drift

Download a PDF copy of this information

Spray drift is a topic that has come under increasing focus as the general public take more interest in pesticides, their use and their residues. Spray drift can cause damage to neighbouring crops, the wider environment as well as farming’s image with the public. Not only does it mean valuable product has failed to reach the crop but undesirable and illegal residues can potentially be found in sensitive crops and foodstuffs, placing further pressure on pesticide use. Examples of this include glyphosate contaminating valuable seed potato crops leading to significant compensation claims due to the hugely damaging effects on daughter tubers.

What is it?

Put simply, spray drift is the movement by wind of any pesticides away from the targeted area. Normally this will take the form of very small droplets during the application process.

There are four main factors that influence spray drift:

- Operator skill and care. An experienced, responsible and capable operator will understand the influence of the other factors and be able to mitigate these as well as ultimately know whether it is safe to spray or not.

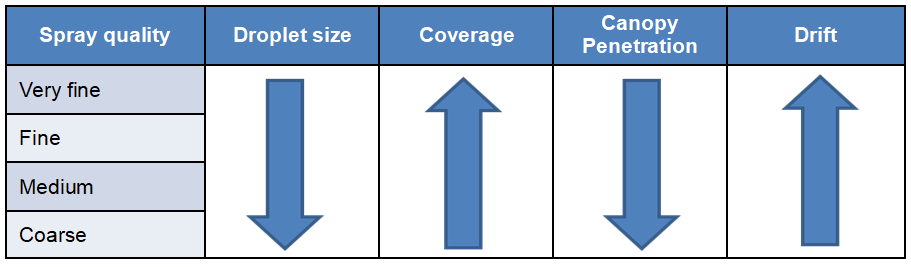

- Spray characteristics. Pesticide solutions will vary due to their differing formulations and droplet size, affecting how susceptible they are to drifting and what measures need to be taken. Larger, heavier droplets will reach their target quicker due to gravity and are less likely to drift. Smaller, lighter droplets however are more susceptible to the effects of drag, meaning they will move more slowly or be more likely to be suspended in the air, potentially leading to spray drift.

- Equipment and application techniques. Different nozzles through to standard of equipment can all influence the likelihood of drift.

- Weather conditions at the time of application. This includes wind direction and speed, relative humidity and temperature. In addition, the airflow through the field can also be affected by obstructions, which will vary with their proximity to the sprayer. Ideally spraying should be undertaken in cool, humid conditions with the wind between 2 – 4 mph.

Reducing spray drift

There are a number of ways spray drift can be minimised.

Product label – Always read and follow the information provided

All spray container labels will contain information relating to buffer zones when spraying near water. This can be influenced by the types of sprayer and in some cases undertaking a Local Environment Risk assessment for Pesticides (LERAP), along with the use of three or four star low drift nozzles, which can allow a reduction in the buffer zone, although again this will be specified on the product label. Information on other no-spray zones and conditions along with application and equipment requirements will also be found on the label and must be adhered to. In addition, buffers in accordance with Good Agricultural and Environmental Conditions (GAEC) and cross compliance must be followed when spraying near land features e.g. hedges.

Wind speed and direction – be aware of the likely conditions and stay alert for changes

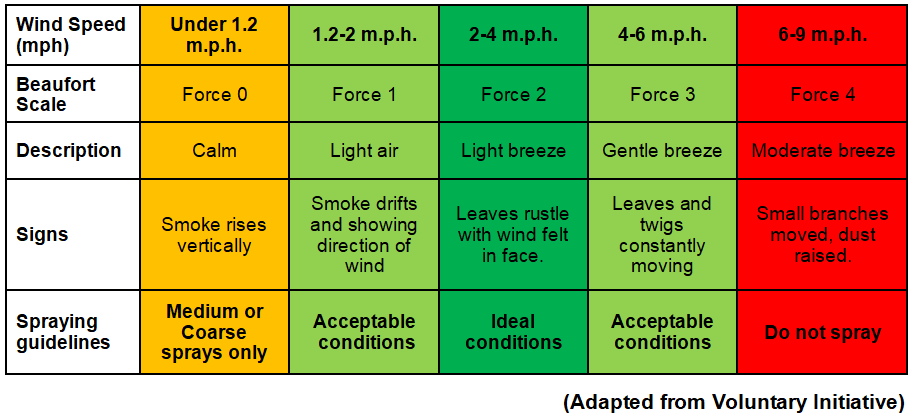

Spraying when the wind speed is between 1.2 and 6 mph is the optimum window with ideal spraying conditions between 2 and 4 mph. Above this, there is a high risk of spray droplets reaching neighbouring fields and crops. Conversely, below this there is the danger of temperature inversions occurring. This is where spray droplets can remain suspended in the still air due to temperature differences between the soil and the air with this more common early in the morning, and in the evening, and should be avoided if possible.

Table 1: Wind speed indicators and suitability for spraying

Sprayer operators should be aware of local forecasts prior to application. With most forecasts quoting the windspeed at 10m above ground level, the general rule of thumb is that the wind speed will be about half this at the ideal nozzle and boom height. Ground cover can influence this with wind speed likely to be greater above bare ground as opposed to growing crops.

Operators should also assess the wind speed and direction both prior to and during spraying as conditions can change quickly. Operators need to ask themselves where could spray drift go to? Are there sensitive crops nearby or even homes or schools? In addition, operators should also consider any obstructions such as trees and buildings and how they will impact on air currents within the field.

Sprayer speed – Keep it steady and don’t go too fast

Spraying will normally be undertaken at 10-12km/hr although this can be reduced according to product label and nozzles. In most situations with the correct boom height and nozzles this will maintain the correct pressure, ensure effective coverage and keep drift to a minimum. There can be pressure to get across the land quicker although increasing forward speed can have a number of effects, all of which can significantly increase the likelihood of drift.

- As forward speed increases, application rates may reduce. In this situation the use of rate controllers may increase pressure to allow application rate to be maintained however increasing pressure also leads to an increase in smaller droplets, which are more likely to cause spray drift. Care also needs to be taken to adjust water volumes and nozzle type to maintain dose rate and crop coverage achieved when spraying at higher than optimum speeds.

- Increasing forward speed will increase turbulence, which again is more likely to create the conditions whereby drift can occur.

- Increasing forward speed will also impact on boom stability and height. This will reduce coverage of the crop with the instability and varying boom height also increasing the likelihood of drift.

- Boom stability and in turn drift can also be affected by sudden changes in speed so operators should drive smoothly at a steady speed.

Temperature – Keep it cool

Apart from the aforementioned temperature inversions, operators should avoid spraying when temperatures are around 25°C or above. At these levels, particularly with low humidity, unpredictable air currents can occur, creating the conditions for spray drift.

Boom height – The lower the boom, the lower the drift

Operators should be aware of the height of their target - is it the ground, the top of the crop or even the top of the weeds. Most modern nozzles provide optimum coverage when the boom is 0.50m above the target when at 0.50m spacing. Any higher and not only is crop penetration and spray pattern affected, but the risk of spray drift is significantly increased. There may also be boom stability issues as boom height increases.

Nozzle choice – Use the right nozzles for the job at the right pressure

Choosing the correct nozzles affects not only the spray quality and potential coverage of the spray but also the likelihood of spray drift. Different tasks require different spray qualities - for instance coarser sprays are preferred for pre-emergence sprays to soil but when spraying insecticides, a fine spray may be better. Some nozzle types e.g. Air Induction offer a reduction in drift over standard Flat Fan nozzles. Nozzles should always be checked regularly for effectiveness with any worn nozzles replaced.

The product label will advise the correct spray quality for the product with the choice of spray quality also taking into account the target, the product and weather conditions. Choosing the right nozzle for the job and using them in a safe and responsible way by factoring in the spray quality ensures that not only maximum efficacy is achieved but also that drift is minimised.

Table 2: Factors to consider when choosing a spray nozzle

When applying sprays near the water environment the advent of LERAPs and the star rating system for nozzles means the use of 3 or 4 star rated nozzles can reduce drift by 75% and 90% respectively at lower pressures. As spray pressure is increased however, spray drift will increase even with the use of 3, or 4 star nozzles, negating their drift reducing benefits. Operators should consult manufacturers recommendations with effectiveness at higher pressures differing between nozzle manufacturers, ranges and types.

Reducing operating pressure will also increase droplet size and reduce drift however flow rate will be compromised so larger nozzles sizes may be needed to maintain application rate.

Spray volume

With time at a premium some operators are looking to apply sprays at reduced water volumes. While in most cases dose rate is maintained, with the spray concentration increased, the reduced volumes can lead to a reduction in droplet size with a subsequent increase in the potential for drift. Reduced volumes may bring logistical benefits however there is a trade off in terms of spray coverage of the crop – operators should never be tempted to increase spray pressures to compensate, with increased pressures resulting in smaller droplets and an increased likelihood of drift. As always product labels should be consulted with some products prohibiting reduced volume applications.

Reducing spray drift should be the aim for all spray operators.

By using the right equipment in the right conditions and by paying heed to label advice, spray drift can be minimised - ensuring that all the product reaches the targeted crop in the most effective manner.

Download a PDF copy of this information

Other information notes in this series include:

- Pesticide Information Note: Pesticide Containers - cleaning and disposal

- Pesticide Information Note: Buffer Zones

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service