Pesticide Information Note: Pesticide containers - cleaning and disposal

Download a PDF copy of this webpage

Pesticide container cleaning

The application of pesticides inevitably results in the production of waste, principally in the form of pesticide containers and packaging. These can, if incorrectly managed, be dangerous to both humans and animals as well as leading to point source pollution incidents. Run-off containing even a single drop of pesticide is capable of causing significant damage if it finds its way into the water environment.

IMPORTANT: You have a duty of care and a legal responsibility for all wastes produced or handled on your farm. You are responsible for the storage, transport and ultimate disposal of these wastes.

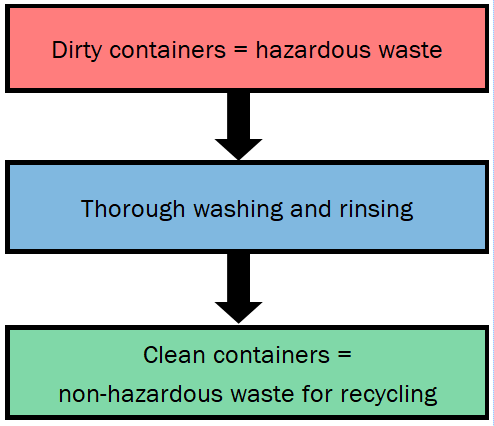

Dirty, empty containers are deemed hazardous waste therefore careful consideration must be given to the safe handling and disposal of pesticide containers. Hazardous wastes can be expensive to dispose of, requiring the use of contractors licenced with SEPA. In addition, there is a significant administrative burden and requirement to retain records.

Thorough washing and cleaning can remove 99.99% of the pesticide product (European Crop Association). Not only does this significantly reduce the risk of poisoning and the risk to the environment but crucially it also means that pesticide containers are no longer classified as hazardous wastes and can be disposed of much more cheaply and simply through a farm plastic recycling service.

There are two main ways of cleaning pesticide containers, pressure rinsing and manually triple rinsing, discussed overleaf. When rinsing dirty containers, operators must wear appropriate PPE (personal protective equipment) and follow the pesticide container labels for safety instructions.

Top Tip

Containers should always be cleaned and rinsed at the time of use, not laid aside for another day. Not only does this ensure all product is utilised but chemicals can become very hard to clean from the sides of containers if allowed to dry.

Pressure rinsing

Modern sprayers are equipped with high pressure rinsing equipment in their induction tanks. These should be used wherever possible as it offers the quickest, easiest and most effective solution. Any spills can also be caught within the hopper and with less handling involved, is safer for the operator.

There are several different types of nozzles and it can be worth having two different types fitted depending on the residues to be cleaned. Nozzle types include:

- Multi hole static balls.

- Rotating nozzles with fan jets.

- Blade type nozzles which direct narrow blades of water upwards, useful for stickier residues e.g. chemicals in suspension form.

It is also important that water pressure is sufficient for the nozzles to work effectively and operators should always check manufacturers guidance for optimum performance.

- Taking water from the clean water tank, place the container over the nozzle.

- To ensure proper cleaning, the operator needs to manoeuvre the container around the nozzle so that the jets of water can reach all corners and areas.

- Containers should be visibly clean and rinsed for at least 30 seconds although effective rinsing may take longer in some cases.

- Some spray mixes may contain an adjuvant so a preliminary rinse with dilute spray solution can help remove stickier sprays however clean water must be always used for the final rinsing cycle.

- Once clean, the container should be allowed to drain into the tank for at least 30 seconds.

- Use the nozzles or internal hose to wash the cap fully and store cleaned caps separately.

Manual triple rinse - rinse, rinse and rinse again

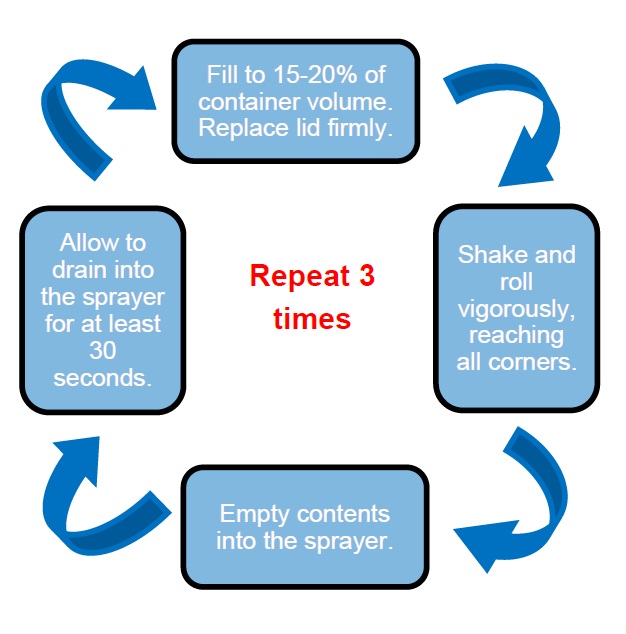

Pesticide containers can also be washed effectively manually using a simple triple rinse system or by remembering the 3Rs - Rinse, Rinse and Rinse again.

- Once empty the container should be filled to around 15 to 20% of volume with the lid firmly replaced.

- The container should then be shaken vigorously for a period. Shaking up and down, side to side and rolling the container over and over should see all corners rinsed thoroughly.

- The container should then be emptied into the sprayer with rinsate allowed to drain from the container for at least 30 seconds.

- The whole process should be repeated a further two times.

Storage and disposal

Once rinsed clean and drained, the containers can be left upturned in a bucket or similar to allow them to dry thoroughly and also capture any remaining rinsate. Dry containers should be punctured to prevent re-use and stored in a clean dry place secure from animals or children.

Containers, caps and foil lids are made from different materials and it is worth clarifying with your waste contractor whether each waste should be separated. Each separate waste should then be bagged up according to your waste contractor’s instructions.

Download a PDF copy of this webpage

Need to Contact SEPA? Call the Hotline 0800 80 70 60

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service