Pesticide Information Note: Know Your Nozzles

Download a PDF copy of this information

Making Sense of Pesticide Spray Nozzles

Sprayer nozzles play a vital role in ensuring pesticide applications reach the right target at the right rate. Nozzle choice influences:

- Droplet size and spray quality

- Likelihood of spray drifts

- Application volumes and throughput

- Spray coverage over the crop or soil

Making the wrong nozzle choice or even using worn nozzles that should be replaced can result in uneven application or reduced effectiveness of the chemical. Volumes applied may be greater or less than required and the likelihood of drift increased, potentially polluting watercourses or biodiversity areas or damaging susceptible crops.

Failing to achieve the desired application coverage may also compromise the applications effectiveness and in some cases result in a further applications being required.

Remember the amount of drift is also a measure of how much has missed the target area which is a waste of money.

Nozzle basics

Nozzle colours and codes

Crop sprayer nozzles in the UK have a designated ISO colour coding based on the flow rate. This makes changing between different nozzle types much more convenient and operator friendly. The colours range from Orange, which has the lowest flow rate up to White which has the largest. Nozzles will also have a number code, so a Blue coloured nozzle will be rated as 1.2/3 which relates to a flow rate of 1.2litres /minute at 3 bar pressure and may also be classed as a “03” (International nozzle size) which represents a flow rate of 3 US gallons per minute at 40 p.s.i. As nozzle output increases, so does droplet size.

Spray quality

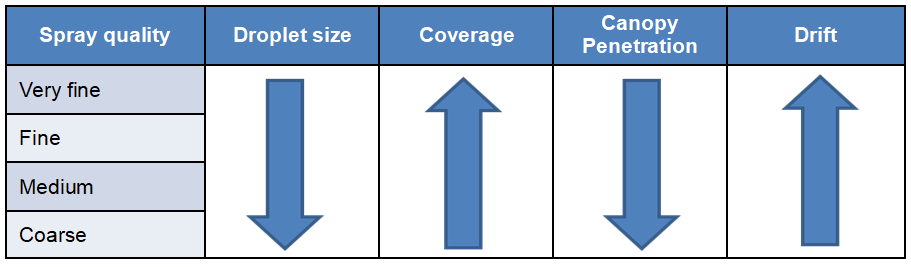

Spray quality is defined by Volume Median Diameter (VMD) with the BCPC International Spray Classification System group and ranges from Very fine, Fine, Medium, Coarse and Very Coarse.

Nozzle design

There are various nozzles designs with each manufacturer also having their own variations. Common nozzle types are:

- Flat Fan- producing a narrow elliptical line of spray in an inverted “V” pattern, typically spread over 110°angle. Evenness of application is achieved when optimum overlap is achieved by correct boom height and nozzle spacing. Common variations of Flat Fan nozzles include many of the nozzles marketed as drift reducing. These include pre-orifice and air induction nozzles.

- Cone – two main types, the hollow cone which produces a ring shaped pattern of finely atomised spray, suitable for high pressures or the full cone which produce a full circular pattern of coarser droplets.

- Streaming nozzles- produces several solid streams of liquid, more suited to liquid fertiliser applications.

Choosing the correct nozzle

Selecting the correct nozzle involves finding the nozzle size (or colour) with the desired output when application volume, forward speed and nozzle spacing are considered. Once this is known the nozzle type can then be selected that produces the required spray pattern, which will be dependent on the target area.

Read the label

The starting point for knowing which nozzle you need is by looking at the label of the chemical container. This will give advice relating to spray volumes (for instance 200l/ha), and in some cases advise of minimum water volumes. In addition, the spray quality required may be advised which can vary depending on the target. This will also list any environmental requirements e.g. LERAPS or buffer zones which can also impact on nozzle choice- i.e. whether a low drift nozzle is required.

Figure 1: Typical spray pattern from a Flat fan nozzle and coverage- with a correctly set up machine ensuring that overlapping provides even overall cover of the crop.

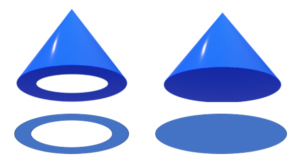

Figure 2: Top and bottom left: Hollow cone spray pattern and coverage. Top and bottom right: Full cone spray pattern and coverage.

Choose the water volume application rate

Although the pesticide label may specify the spraying volume, in other cases, volume application rate should consider what is to be achieved. This may be 200l/ha, or be higher or lower depending on requirement. Lower water volumes can increase work rates however higher rates may be needed to penetrate dense crops.

Forward speed

Forward speed can influence work rates however going too fast can lead to increased drift and reduced canopy penetration as the sprayer and boom will be much less stable and the spray will be subject to greater turbulence. Typically work rates are 8 -12 km/hr. A simple calibration to check forward speed or the use of GPS equipment can help ensure accuracy.

Know your pressure

Pressure has a huge influence in spray quality. As pressure increases, droplet size decreases. Finer sprays will offer greater coverage with reduced canopy penetration while lower pressures, with bigger droplets will be less susceptible to drift and will offer better penetration.

What spray quality do you need?

For many uses a medium spray quality will be selected and be regarded as the default, however for certain tasks other spray qualities will be required depending on the intended target of the application. Different spray characteristics are shown in the table below:

Table 1: Factors to consider when choosing a spray nozzle

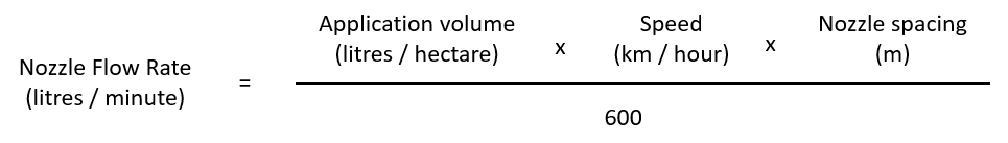

Calculate your flow rate

Selecting the correct nozzle requires knowing the flow rate required that best achieves the desired application volume at the preferred speed, and can be calculated as follows:

Select your nozzle

Most nozzle manufacturers will have simple charts which can advise which nozzle (or nozzle colour) is best depending on the required flow rate. These will also give an indication of how the spray quality of the nozzle changes at different pressures. In recent years this has been taken a stage further with the availability of Apps for this process. It may also be necessary to fine tune the selection process. This is best done by making slight adjustments to forward speed.

Once the nozzle output has been determined the type of nozzle can be chosen. A HGCA funded study and guide into the merits of each nozzle type and suitability for different applications can be found here. There are a wide variety of nozzles available for most tasks with an increase in recent years in the number of nozzles available for pre-emergence sprays which can achieve the desired outputs and soil coverage, yet also offering drift reduction.

Top Tips

- Regularly calibrate equipment! Don’t assume that throughputs and performance will remain the same through the entire season.

- Make sure nozzle outputs are within 10% of manufacturers specification- if not, change them and keep a stock of replacements.

- Always check forward speeds and system pressure gauges are accurate.

- When using low drift nozzles e.g. air induction, always check these can be used with the chemical being applied.

- Not all nozzles are the same- always read manufacturers guidance for best results.

Download a PDF copy of this information

Other information notes in this series:

Need to Contact SEPA? Call the Hotline 0800 80 70 60

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service