Meeting Your Market – Milk Hygiene Quality

30 January 2023While the base milk price is out of the control of farmers selling to a processor, there can be a big difference in the milk price received depending on the compositional and hygiene quality of the milk. Penalties for hygiene quality can vary significantly between processors, and could cost up to 2ppl based on a somatic cell count (SCC) between 251,000-300,000 cells/ml and a Bactoscan of 30,001-50,000 cells/ml. For a 200-milking cow herd averaging 28 litres/day that is a loss of £3,360/month.

The factors involved in maintaining hygiene quality will also benefit the herd by helping lower the incidence of mastitis infections, improve milk sales and animal welfare, while reducing the culling rate and veterinary costs.

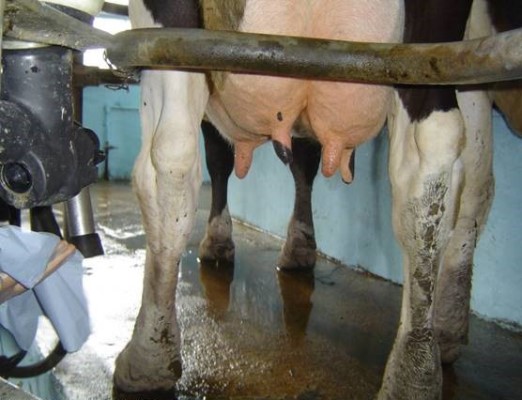

The key factors influencing SCC and the Bactoscan are very similar. It all starts with ensuring the housing environment is as clean as possible. This includes bedding management, keeping passages clean with frequent scraping and even nutrition to ensure optimal muck consistency to help keep cows and the udder as clean as possible.

Keeping accurate mastitis records and reviewing trends in SCC’s can help identify persistently high cell count cows to aid culling decisions. Cows should be culled if they experience three mastitis infections in the same quarter in a lactation or five or more infections in any quarter in the same lactation.

High Bactoscans can result from three main areas: a dirty milking plant (including refrigeration failure), environmental contamination or mastitis, with insufficient plant cleaning being the most common cause.

The Milking Plant

Key areas to investigate/manage include:

- Build-up of milk residue (including the plate cooler).

- Regular inspection and replacement of liners/rubberware if worn/cracked.

- Cleanliness of milking units.

- Correct temperature of the wash cycle.

- Plant cleaning with the appropriate chemical and concentration at the end of each milking, as well as the bulk tank being rinsed and cleaned after each collection.

- Refrigeration process: milk must not enter the bulk tank at more than 18˚C and it should be cooled to less than 7˚C within three hours of milking.

- Check separate clusters used for newly calved or mastitic cows.

- Regular parlour testing at least once/year depending on operating hours; including include both a static and dynamic test (for more information see https://www.fas.scot/downloads/milk-manager-news-march-2022/).

Environmental Contamination

Environmental contamination mainly results from poor teat preparation in the parlour and dirty environmental conditions. Use a pre-dip if mastitis from environmental pathogens is an issue. Also ensure teats are dry before applying the milking unit, as dirty water can run down to the end of the teat, taking bacteria with it. This will greatly increase the risk of bacteria entering the udder during milking.

Bedding is also a key source of environmental bugs. Quantity and frequency of bedding are important but so are the cubicle dimensions to achieve the correct lying position to avoid muck in cubicles. The incidence of muck at the back of cubicles should ideally be one dirty cubicle in ten. Using kiln dried sawdust over fresh sawdust also reduces the risk of mastitis causing bacteria found in sawdust, especially Klebsiella.

If the coliform count from a bulk tank sample test is over 20cfu/ml, it can indicate that udder preparation needs more attention and pre-dipping may help to reduce Bactoscans further.

Mastitis

The second most common cause of Bactoscan failure is mastitis, particularly cases caused by environmental bacteria (especially Streptococcus uberis). While cows may not show clinical signs, infections caused by S. uberis (and Streptococcus agalactiae) can shed very high numbers of bacteria (and up to 1,000,000cells/ml from clinically infected quarters). Therefore, only a very small number of infected cows are needed to result in a high Bactoscan.

Reduce mastitis transmission between cows from the milker’s hands by wearing gloves and the gold standard procedure is to disinfect gloves at the end of each row of cows.

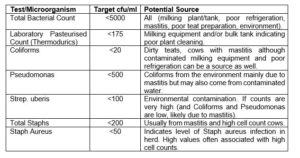

Bulk tank milk sample analysis can help identify the source of the problem by looking at the presence of different types of bacteria in milk (see table below).

Targets for Bulk Tank Milk Analysis

Source: Gloucester Laboratories, Wood Veterinary Group

lorna.macpherson@sac.co.uk; 07760 990901

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service