Silage Clamp Management – a Winter Investment

14 December 2020Silage quality throughout the winter months is vital for maintaining milk production. Prior to formulating rations for the winter, it is key to get a silage analysis from each clamp to understand the quality of the silage. Using the silage analysis results, rations can be accurately formulated according to milk yield, milk quality and stage of lactation. Ideally, silage quality should be checked every four weeks and rations adjusted accordingly. If silage analysis cannot be performed as regularly as every four weeks, then a silage analysis should occur when the clamp is opened and halfway through the clamp.

There can be variations in silage quality throughout the clamp with up to 12% dry matter (DM) losses occurring over time. Therefore, if silage is not analysed, the ration being fed out when you reach the back of the clamp may not be providing the correct requirements for the cow. Similarly, silage quality can vary across the clamp face, so it is vital to ensure that when sampling the silage, a representative sample in a ‘W’ shape is taken. From side to side of the clamp face, variations in DM, crude protein and neutral detergent fibre (NDF) can occur by up to 8%, 3% and 10%, respectively. Similarly, from the bottom to the top of the clamp face, DM can vary by up to 10%, whilst energy density of the clamp face can vary by 1.6 MJ ME/kg DM. Taking a representative sample will ensure these variations are accounted for in the results.

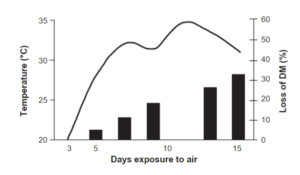

Clamp face management is vital in reducing spoilage and variations in quality; an untidy clamp face allows oxygen into the silage due to the larger surface area. The presence of oxygen will lead to spoilage and a poorer quality of silage being fed out to the cows, which may reduce intakes and milk production. Spoilage and heating within the clamp occur due to the growth of yeast and microbes in the presence of oxygen, which will consume energy from the silage lowering its quality. As seen in Figure 1, when the silage is exposed to oxygen, the temperature rises and DM losses increase over time. Ideally, the clamp face should be smooth and tight to reduce silage losses. This can be achieved by ensuring your cutting device is sharp and that the silage has been well consolidated during clamp filling.

Figure 1. The effect of heating in maize silage on DM losses when exposed to air.

Source: Wilkinson and Davies, 2012.

Source: Wilkinson and Davies, 2012.

The top sheet should only be pulled back as required to allow for silage removal; if the sheet is pulled too far back there is potential for losses due to aerobic spoilage. If the clamp is outside, there is a chance the silage may be rained on which can lower DM content, impacting the ration and potentially intakes. It is important to remove the top waste present on the clamp prior to feeding out, as this spoiled silage would lower the nutritive value of the ration and has the potential to lower feed intakes due to poor palatability. It may also be a mycotoxin risk. Any top waste or spoiled silage that has been removed from the clamp should not be left near the clamp to reduce close contact of undesirable microbes. If these microbes are in close contact to the clamp face, they could spread and start to grow, thus reducing silage quality.

Time spent managing your silage clamps during the winter months should be seen as a good investment for the business, as keeping silage quality high will maintain intakes and milk production.

Reference:

Wilkinson, J.M., & Davis, D.R. 2012. The aerobic stability of silage: key findings and recent developments. Grass and Forage Science. 68, 1-9

Cara Campbell for the Farm Advisory Service

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service