The Ground Preparation Contractor – Preparing for woodland planting (FWN32)

19 June 2019Fail to prepare, prepare to fail. This old advice could be applied to any project but it’s particularly true for woodland planting. Creating a favourable growing environment for young trees is essential to get the crop off to a good start and the best way to do this will depend on the soil type and topography of the site.

A forestry agent will be able to advise on the most appropriate form of cultivation but there’s more to consider in actually getting the job done. Craig Cochrane started his forestry groundwork business 20 years ago, with his son Scott on board for the last four years. Together they employ a team of eight people, doing ploughing, mounding and drainage for woodland creation and restock sites. Craig and Scott shared some of their experience and advice on getting ground preparation right.

The right method and the right machine

Most woodland creation sites are prepared either by ploughing, mounding or scarifying. Different types and sizes of the plough will achieve different levels of cultivation and continuous mounders are an efficient way to turn over consistent raised planting positions at a specified  density. Excavators can cover the less accessible areas by turning over mounds with the bucket on each spot, or dolloping mounds with spoil from drainage ditches. Scarifiers can be used on drier sites to clear vegetation and do more shallow cultivation than ploughing. Ground preparation contractors will sometimes see a need for a new type of machine and build it themselves. For example, Cochrane Forestry Ltd has designed a mechanical screefer which provides minimal cultivation that would otherwise have to be done by hand.

density. Excavators can cover the less accessible areas by turning over mounds with the bucket on each spot, or dolloping mounds with spoil from drainage ditches. Scarifiers can be used on drier sites to clear vegetation and do more shallow cultivation than ploughing. Ground preparation contractors will sometimes see a need for a new type of machine and build it themselves. For example, Cochrane Forestry Ltd has designed a mechanical screefer which provides minimal cultivation that would otherwise have to be done by hand.

The choice of vehicle used to run the cultivation machinery will depend on the nature of the ground and ease of access around the site. Tractors will be suitable for much agricultural land and can be fitted with double wheels if necessary. Tracked or crawler vehicles will manage more difficult terrain, and standard and low ground pressure excavators can work on softer ground.

Walk the site with a forestry agent to decide what cultivation method to use, and share your knowledge of the ground. If they see it on a dry summer’s day but you know it’s a quagmire in winter, tell them. How wet or dry a site is, is an important consideration in how best to prepare the ground for planting.

Similarly, if the cultivation method is chosen when the ground is heavily grazed then livestock are removed, the ground may be quite different by the time the work is about to start, and the method originally planned may no longer be appropriate. The type of ground preparation to be used must be specified in applications for Forestry Grant Scheme (FGS) funding. If what was originally proposed is no longer the best-suited method for the ground the Forestry Commission may need to approve the change and amend the application. It is better to do this than go ahead with a cultivation method that won’t provide the best growing conditions for the new woodland.

First, seek professional advice on what cultivation method will be most effective on the ground you’re going to plant. On larger or variable sites you might need to use different methods of ground preparation, or different machines on different areas. These might be rocky areas where a plough would struggle, or slopes too steep for a tractor.

Very often there will be some areas of a site that can’t be covered by the main machine, and an excavator is needed to complete the job, so it’s best to factor this into the budget from the start. If the site needs drainage, you will need an excavator on site anyway, so plan for any excavator  ground preparation to be done at the same time.

ground preparation to be done at the same time.

Access to the site is the next consideration. Machines might be brought to the site by an articulated lorry. If the farm road isn’t suitable for lorries a low-loader or tractor and trailer can be used, or machines may have to track in. Any constraints on how the machines move around within the site should also be addressed early on, for example, crossing over watercourses or under powerlines.

Usually, ground preparation should start at the furthest point of the site and work back towards the main access point. This avoids running over cultivation that’s already been done, and excessive tracking in and out which can damage the ground, particularly in wet conditions. Tractors will need to return to the gate each night to refuel but excavators can take a bunded fuel bowser with them as they work around the site. This allows machines to be left where they’re working if the drivers can walk or use a quad bike to get in each day.

Where more than one machine is being used, it makes sense for them to work nearby, so that someone is on hand to help if one machine gets stuck. Particularly if an excavator is filling in the areas that the primary machine can’t do it’s a good idea for them to work together.

Often, the fencing and ground preparation work can overlap, providing the ground preparation leaves access routes for the fencers, and the fencers leave a gap in the fence for machines to enter and exit the site. If any sections of the fenceline need to have the ground levelled out, it makes sense to use an excavator that needs to be on site anyway. It’s best to avoid an overlap with the planting operations, and the cultivation will benefit from having a period to settle, ideally with a few showers of rain, before planting begins. Contractors will want to have large-scale

jobs in the diary well in advance, but may have some flexibility to fit the smaller jobs around them. Unpredictable weather can sometimes mean one over-running job will delay another. It helps if all parties can be flexible but it’s still best to agree on an approximate start date with the contractor as early as possible.

All vehicles and machinery are vulnerable to breakdown, particularly those working in the demanding environments of woodland creation sites. A little lost time for repairs and maintenance is to be expected but drivers will usually be able to deal with minor problems on site. There are often mechanics amongst the team who can be called out for bigger repairs.

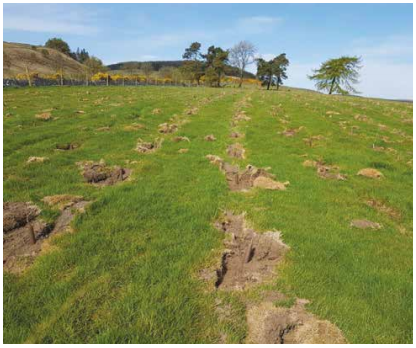

Weather can delay work if the ground turns soft or slippery, and it may become dangerous to run the machines on slopes. When the ground becomes very wet machines may cause deep rutting or get stuck. If a period of dry weather is followed by heavy rain the contractors should monitor the effectiveness of drainage and be prepared to modify the drains and install silt traps to prevent diffuse pollution.

Unfortunately, theft and vandalism are an increasing problem for groundwork contractors. A tank of diesel being stolen will cost the contractor, cause hassle and delay the job. Machines do go missing too, creating a much more serious problem for everyone. Consider letting  neighbours know when the work is happening so they can be aware of suspicious activity, for example, people at the machines on a weekend or evening when the contractors are only working during the week.

neighbours know when the work is happening so they can be aware of suspicious activity, for example, people at the machines on a weekend or evening when the contractors are only working during the week.

Drainage

If you know the site to be planted needs drainage, this work can be done before the cultivation. However, it’s often the case that the places where drainage is needed only become apparent after the ground has been ploughed and water starts to lie at the bottom of furrows. It’s always best to allow for some drainage work in the budget. With the advice of the contractor, decide where to route ditches to avoid sending water into other fields. It’s crucial to include soakaway areas, sump pits and silt traps to avoid polluting watercourses. Drains should not exceed a gradient of 2°.

Poorly drained sites will produce stunted trees not worth the cost of harvesting and increase the risk of losing the crop to wind damage in 15 to 20 years. The initial outlay for drainage work will be paid back many times over if it ensures the crop reaches maturity.

Costs

Ground preparation is charged per hectare. More challenging terrain means a slower work rate and therefore a higher cost per hectare. On steep or wet ground, the machines will probably only cover half the area they would in the same time on easier sites. On steeper slopes, the machines may only be able to work down the hill, and will have to reverse back up to start the next run. This means the time it takes will be double, or more, than where they can work in both directions.

There will be different rates for using difference machines, for example, a tractor and plough can work faster and cover more ground in a day than an excavator turning over individual mounds. For large sites using more than one machine may be necessary to get the work done in a reasonable timescale. As discussed above, there are benefits to having machines working together and only cost in addition to the per hectare rate will be transport for each machine. Drainage is charged per metre and other digger work, such as levelling areas or access routes will be charged at an hourly or day rate.

In the long run, it pays to be realistic about costs. The cheapest way to do something isn’t always the best way and it’s better to budget for more work, rather than less. Getting the ground preparation right gives the trees the best possible conditions to establish and is a crucial investment for the long-term success of a timber crop.

FGS Funding

The Forestry Grant Scheme can provide funding for the initial planting on a per hectare basis. This is intended to support the costs of ground preparation, planting labour Double throw mouldboard ploughing. and the trees themselves.

Craig Cochrane, Scott Cochrane Cochrane Forestry and Groundworks & Leona Baillie for the Farm Advisory Service

This article has been published in the Spring 2019 edition of the Farm Woodland News. Download a copy to access all articles. Subscribe to receive newly published editions via email by using the form here.

Sign up to the FAS newsletter

Receive updates on news, events and publications from Scotland’s Farm Advisory Service